ROLLPASS

Professional engineering company specializing in the design and optimization of hot rolling lines and hot rolling processes for steel product manufacturers. We offer high-quality engineering services tailored to the individual needs of our clients. With our experience and knowledge, we provide reliable solutions in the following areas.

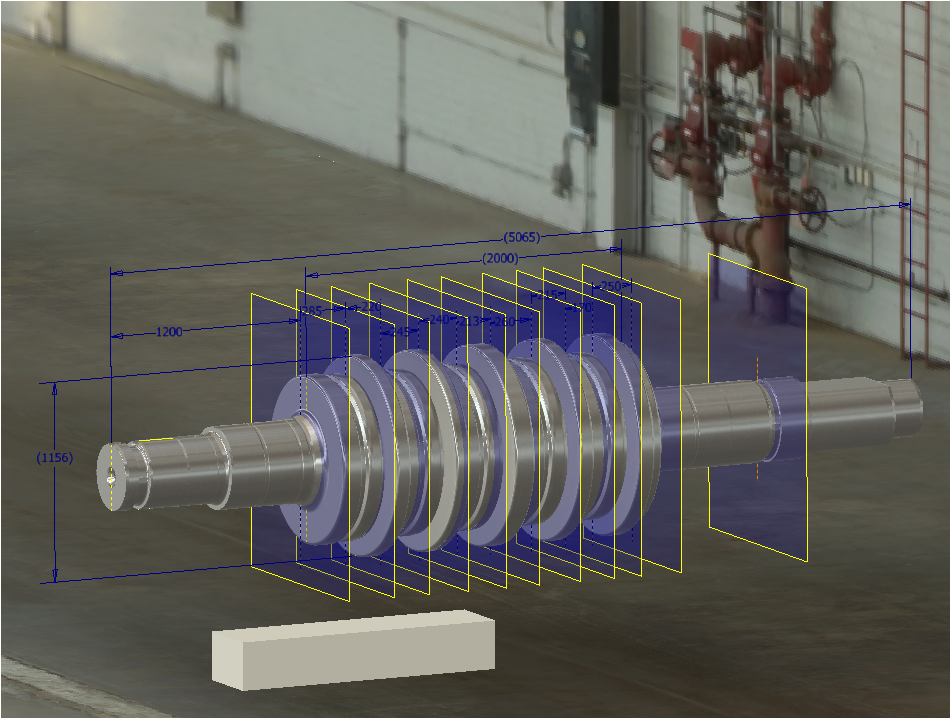

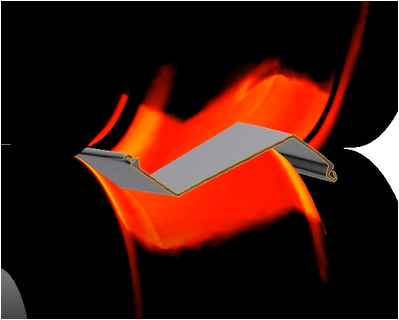

Designing and Commissioning Tools

Maximize efficiency with custom tools for rails, sheet piles, and sections. Engineered for perfection.

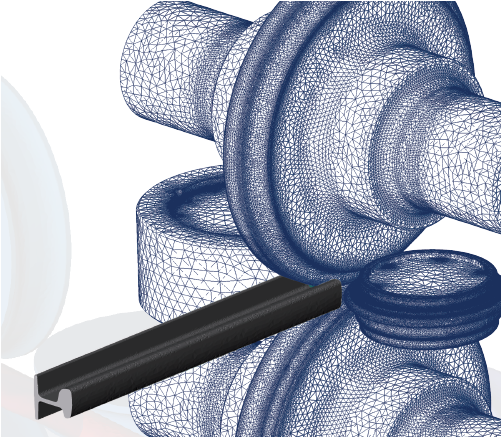

FEM Simulations

Designing new and optimizing existing hot rolling lines and hot rolling processes. Fine-tune operations with simulations. Analyze, optimize, succeed

Roll pass design improvement

Hot Rolling Lines Audits on customer sites. Enjoy seamless operations. Our support keeps you running at lowest costs.

Additional Services

We Also Offer

Technological support during commissioning phase and industrial trials

cost optimization on given mill by leading the continuous improvement projects

Six Reasons For People Choosing Us

Quality

Use only latest trends in Roll Pass Design

Accredited

Unmatched attention to detail, Tailored solutions for your needs

Trained

14+ Years of experience

Time Availability

24 h availability for thrusted customers

Quick Response

24 hour reaction time

Free Design modification

Until the first qualified product passes through the cooling bed, modification fees are waived.

Don’t Know What To Start With?

Schedule a call and ask details guidelines step by step

Each task/order with reference to the cooperation agreement will include stipulations specific to the order, such as:

– the scope of the work

– method of execution,

– and delivery dates.

In the framework of cooperation, we are using the necessary equipment (hardware and software) and resources provided by customer in order to perform the projects.